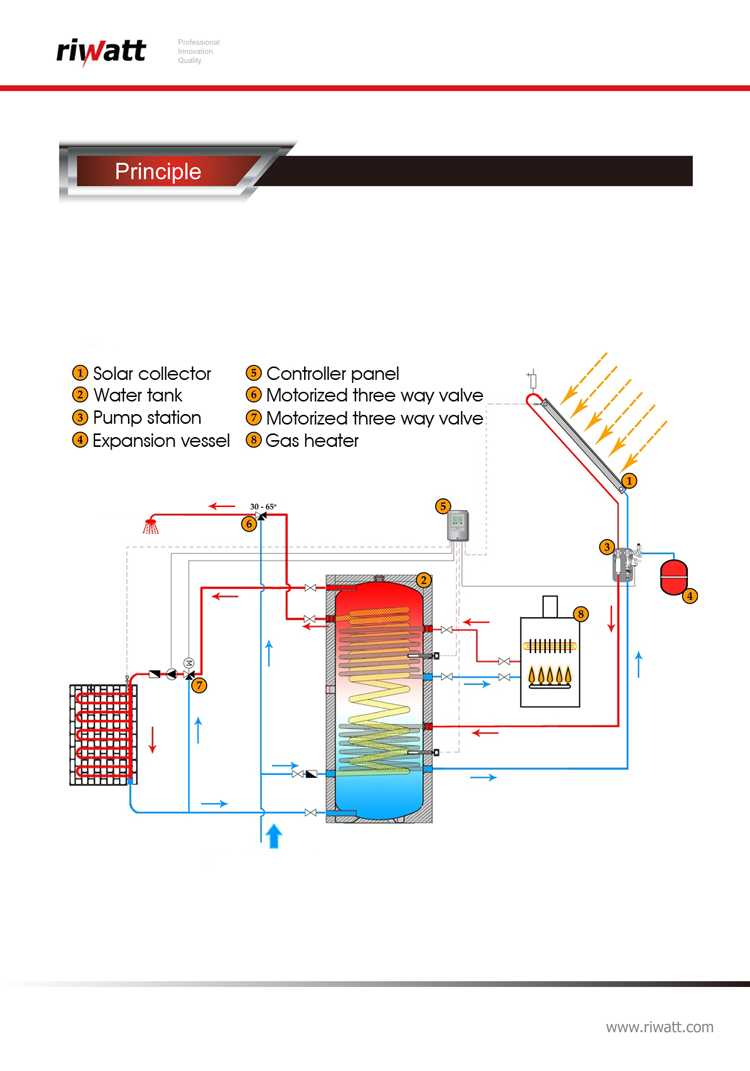

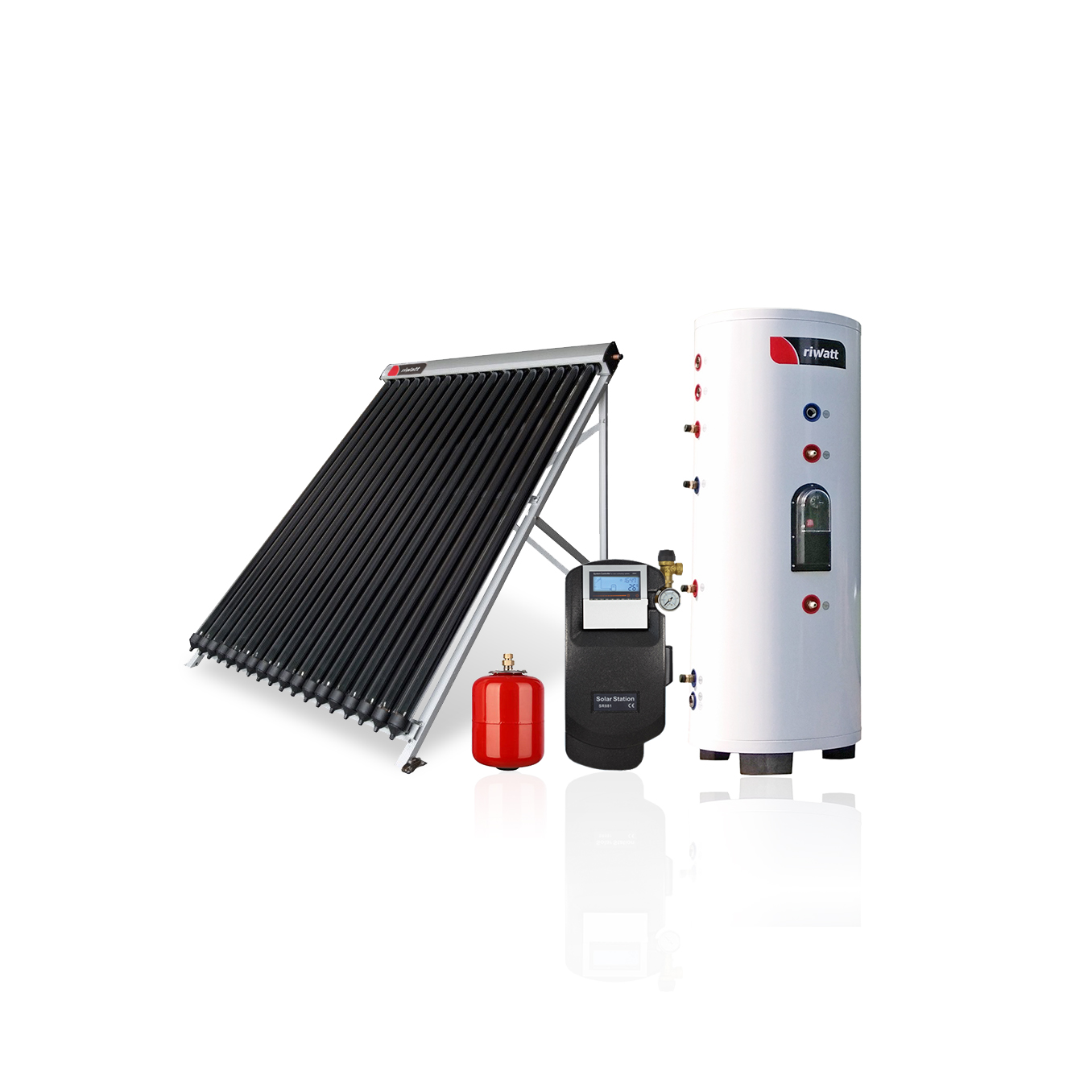

Split solar system is a kind of indirect heat exchange, forced separation of two-cycle pressure hot water system. it realize perfect combination between the solar system and architecture!

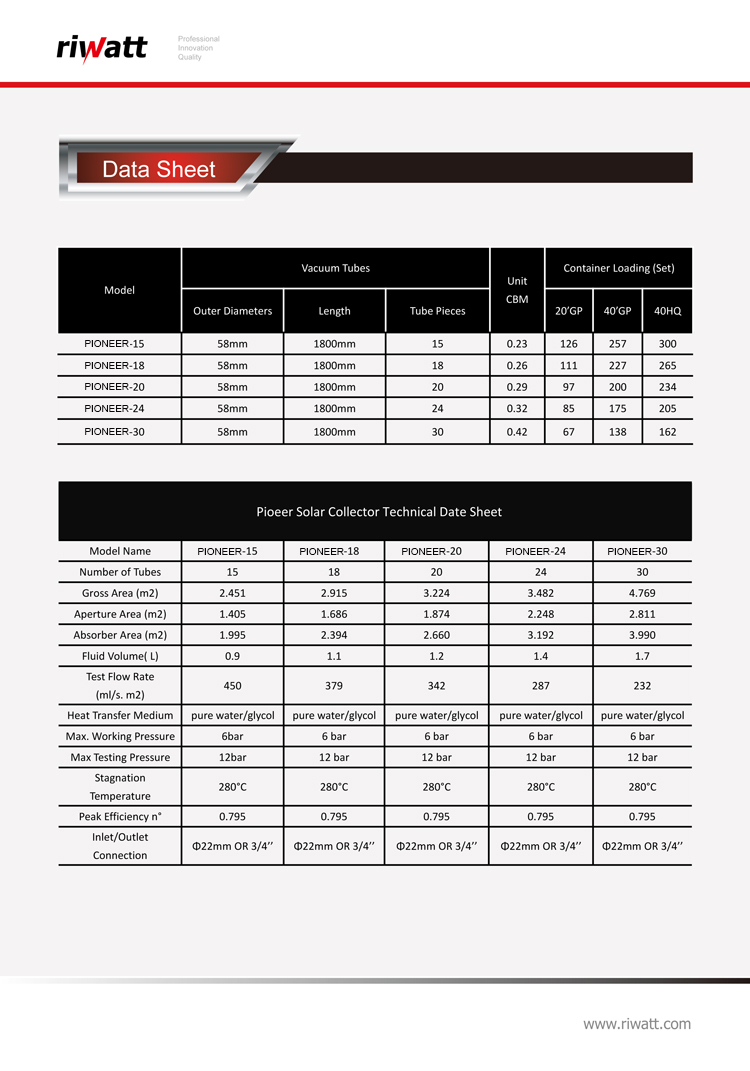

| Evacuated Tube Heat Ppie Solar Collector Technical Parameters | |||||

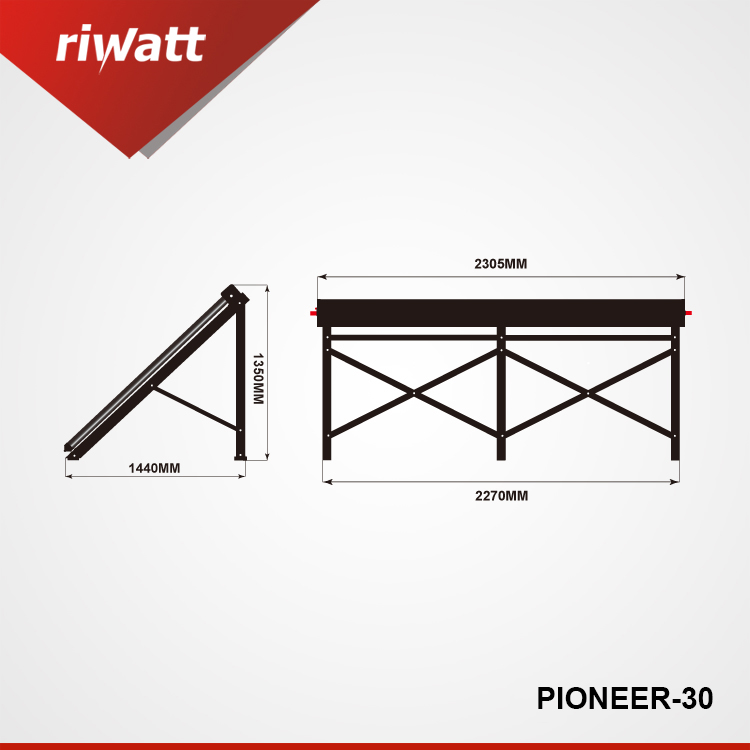

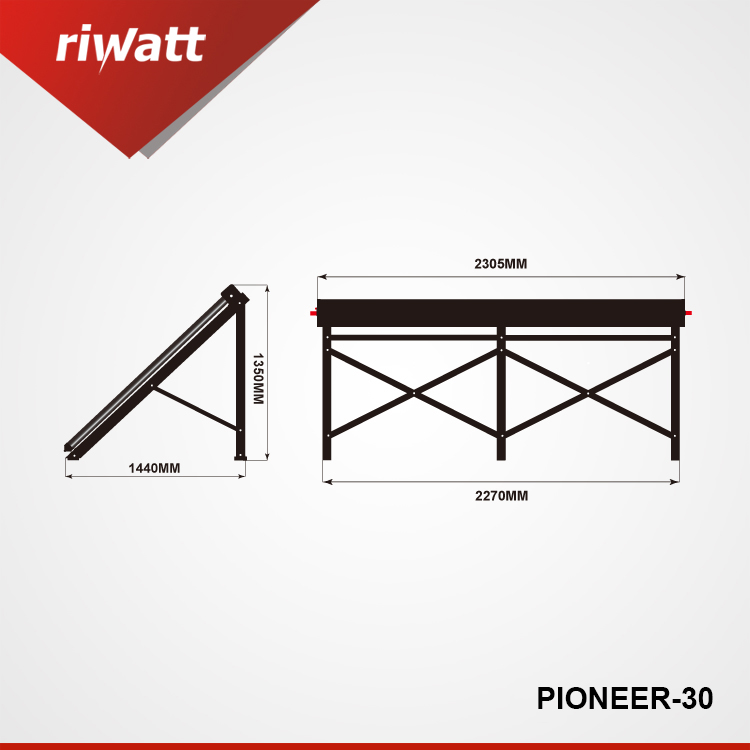

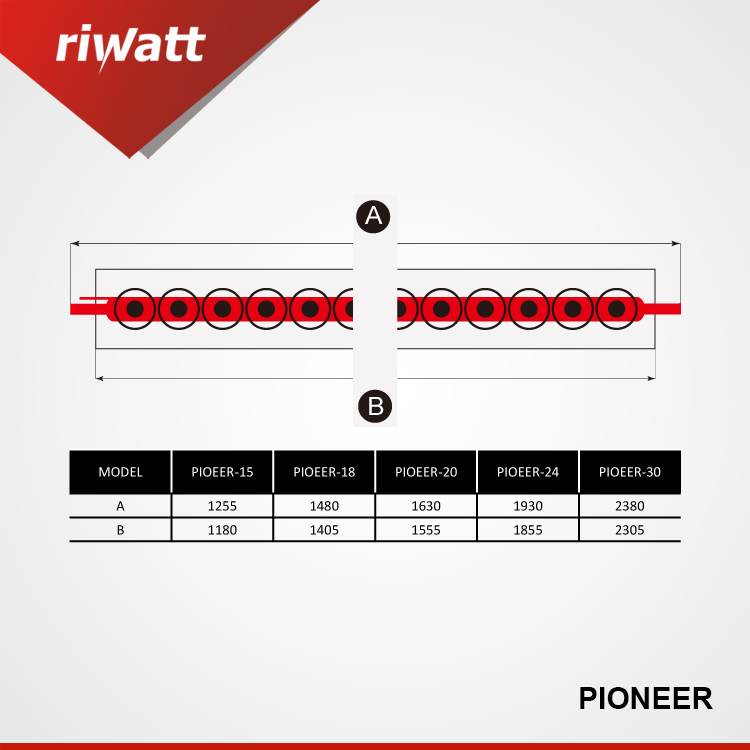

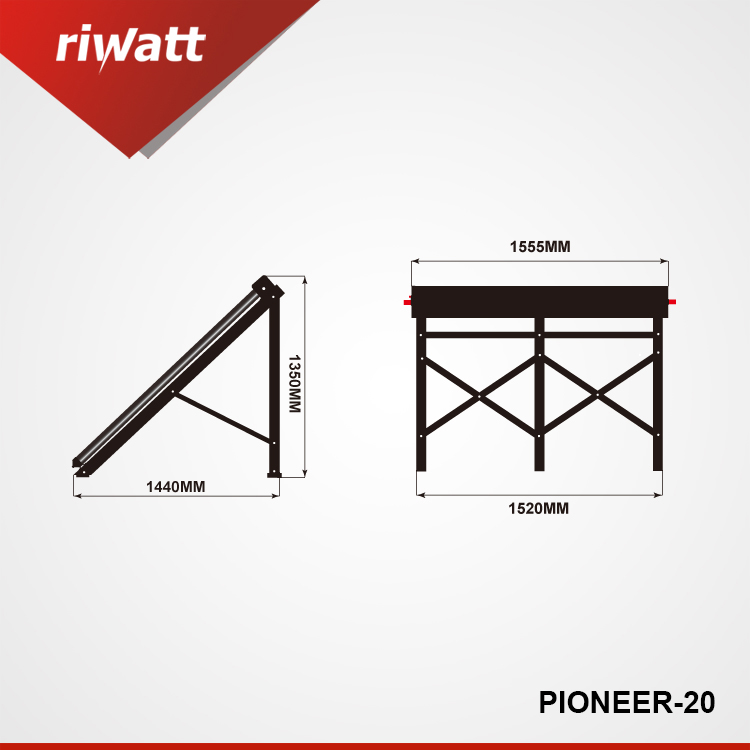

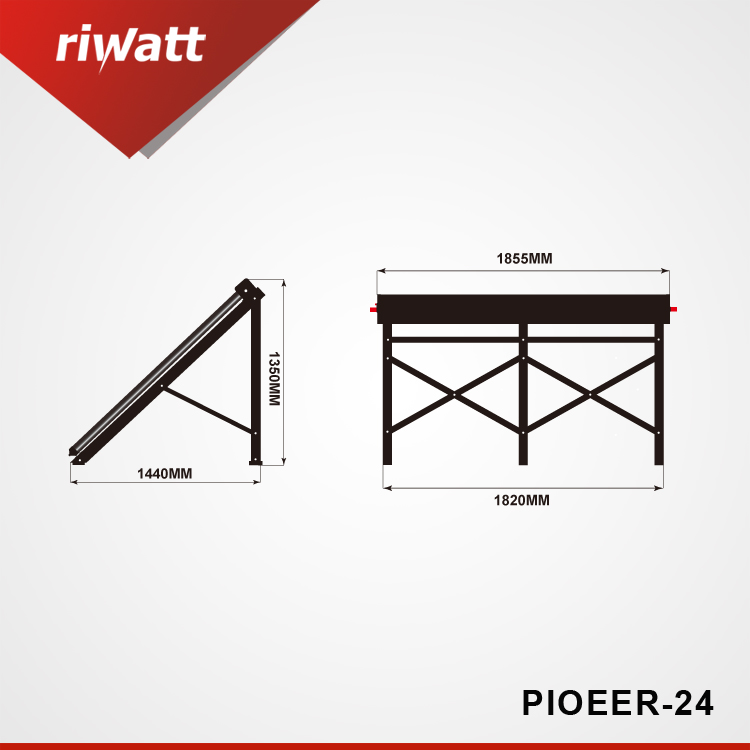

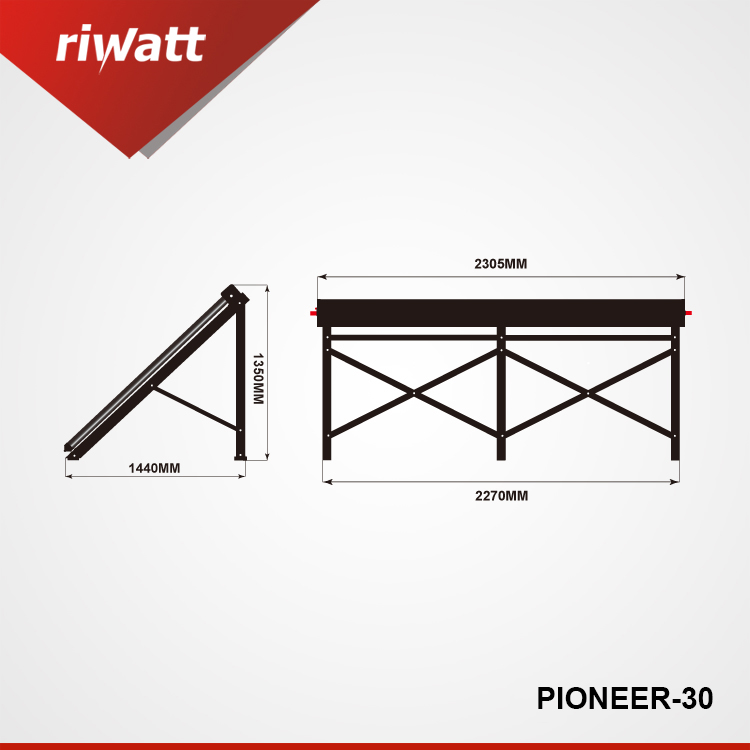

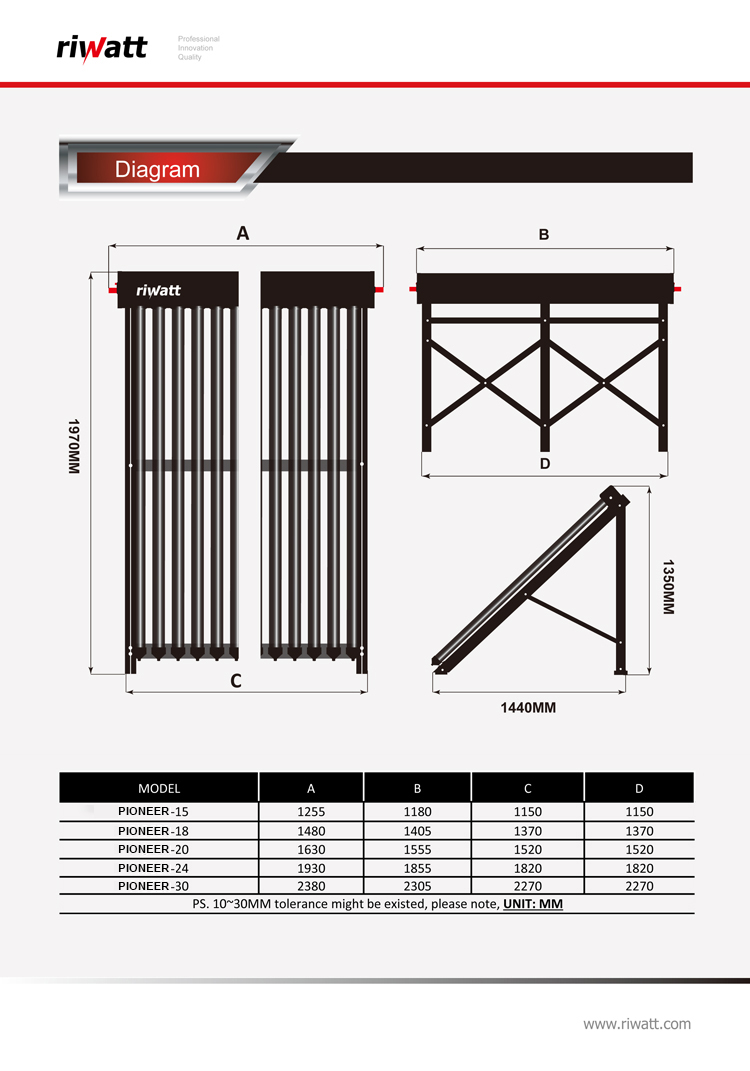

| Specification | PIONEER-15 | PIONEER-18 | PIONEER-20 | PIONEER-24 | PIONEER-30 |

| Absorber Area(m²) | 1.995 | 2.349 | 2.66 | 3.192 | 3.99 |

| Aperture Area(m²) | 1.405 | 1.686 | 1.874 | 2.248 | 2.811 |

| Gross Area(m²) | 2.451 | 2.915 | 3.224 | 3.482 | 4.769 |

| Connection Diameter(mm) | 22 | 22 | 22 | 22 | 22 |

| Collector Capacity(L) | 0.9 | 1.1 | 1.2 | 1.4 | 1.7 |

| Test Flow Rated(ml/s.m2) | 450 | 379 | 342 | 287 | 232 |

| Heat Transfer Medium | Pure Water/Glycol | ||||

| Angle of Inclination(°) | adjustable and non-adjustable(15-90°) | ||||

| Typical Operating Temperature(℃) | -40℃≤T≤130℃ | ||||

| Max. Stagnation Temperature(℃) | ≥230℃ | ||||

| Max. Operation Pressure(MPa) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Thermal Performance | |||||

| Efficiency Equation | η0=0.681-1.60Ti*-0.006GTi*2 | ||||

| Peak Efficiency Intercept(based on aperture area) | η0: 0.795 | ||||

| Yield Forecast(kWh/m²a ) | 579 | 579 | 579 | 579 | 579 |

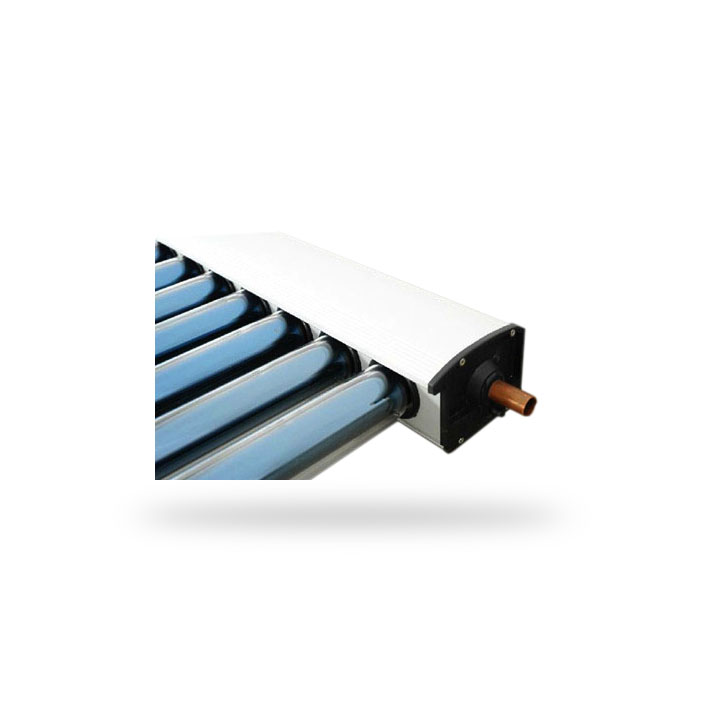

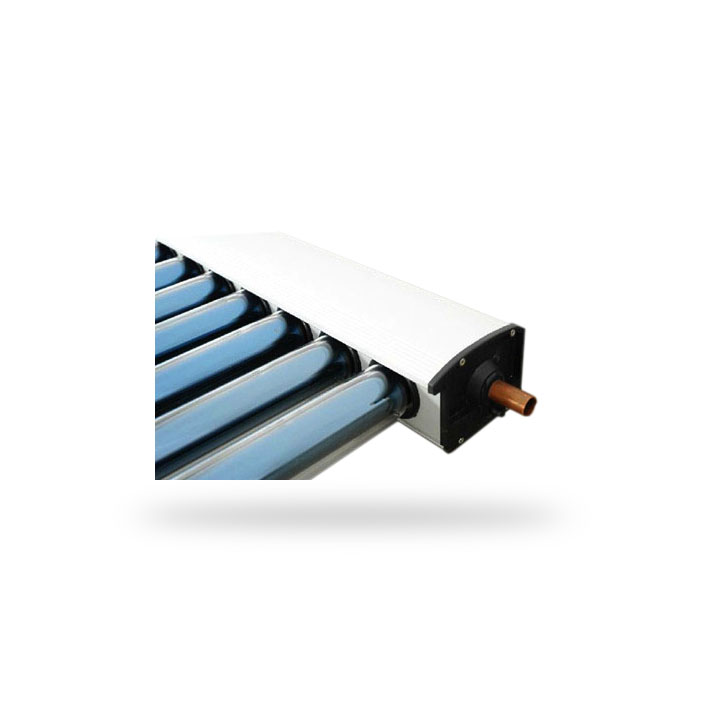

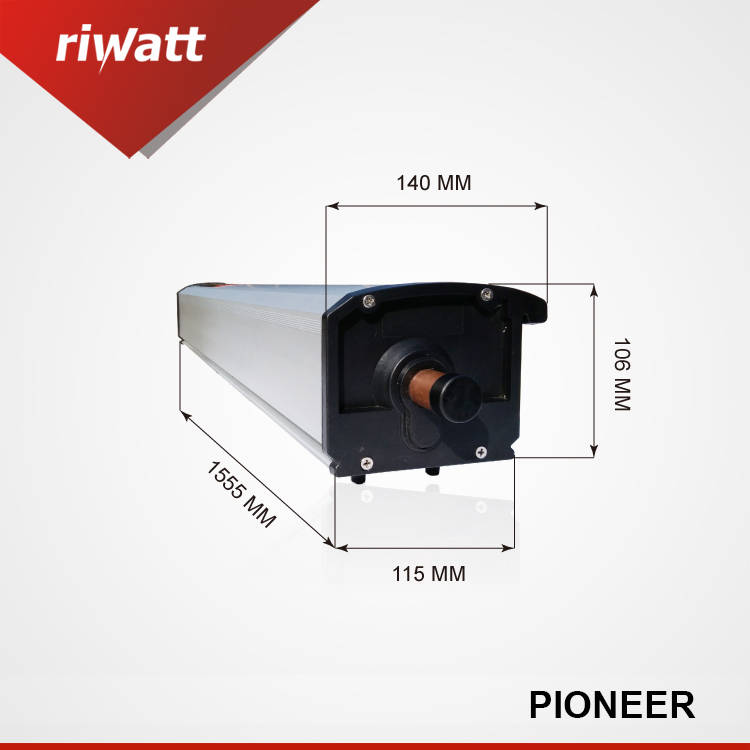

| Manifold Casing | |||||

| Manifold Material | 6063 Aluminum Alloy | ||||

| Color | silvery white or black | ||||

| Insulation | |||||

| Material | High Density Comressed Rock Wool | ||||

| Insulation Factor | K-factor: 0.03 W/(m.K) | ||||

| Evacuated tube | |||||

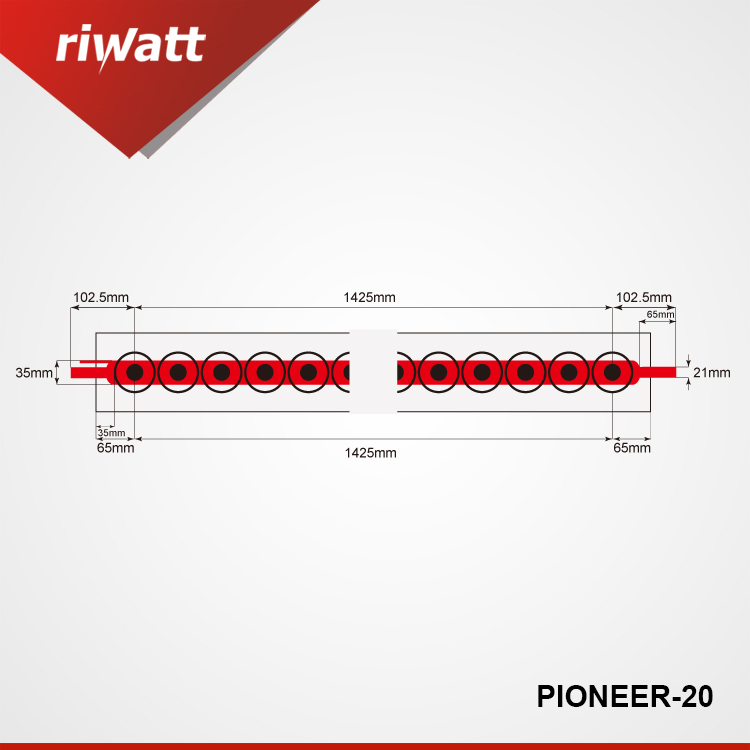

| Specification of Evacuated Tube(mm) | Φ58×1800 | Φ58×1800 | Φ58×1800 | Φ58×1800 | Φ58×1800 |

| Gap Between Tubes | 75 | 75 | 75 | 75 | 75 |

| Number of Evacuated Tubes | 15 | 18 | 20 | 25 | 30 |

| Vacuum Tube Material&Size | High Borosilicate 3.3 glass/58*1800mm | ||||

| Absorber Coating | 【Cu/SS-ALN(H)/SS-ALN(L)/ALN】(Three Target) | ||||

| Coefficient of absorption | 0.93-0.96> 92% (AM 1.5) | ||||

| Coefficient of emission | 0.04-0.06(800C±50C) | ||||

| Heat Pipes& Heat Transfer Fins | |||||

| Working Medium | Super Conductivity Technology | ||||

| Operating Pressure(mm) | 0.7Mpa(max operation pressure) | ||||

| Startup Temperature | ≤30℃ | ≤30℃ | ≤30℃ | ≤30℃ | ≤30℃ |

| Copper Type | TP2 | TP2 | TP2 | TP2 | TP2 |

| Evaporation Part Diameter(mm) | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ8mm |

| Condensation Size(mm) | Φ14/24mm | ||||

| Heat Transfer Fins | 3003 Aluminum Alloy | ||||

| Silicon Ring | |||||

| Material | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber |

| Density | 1.1 Mg/m3 | ||||

| Packing | |||||

| Standard Packing | Foam and cardboard carton | ||||

| Net Weight(kg) | 51 | 60 | 66 | 82 | 99 |

| Gross Weight(kg) | 62 | 72 | 80 | 100 | 115 |

| QTY in 40FT Container(pcs) | 260 | 220 | 200 | 160 | 130 |

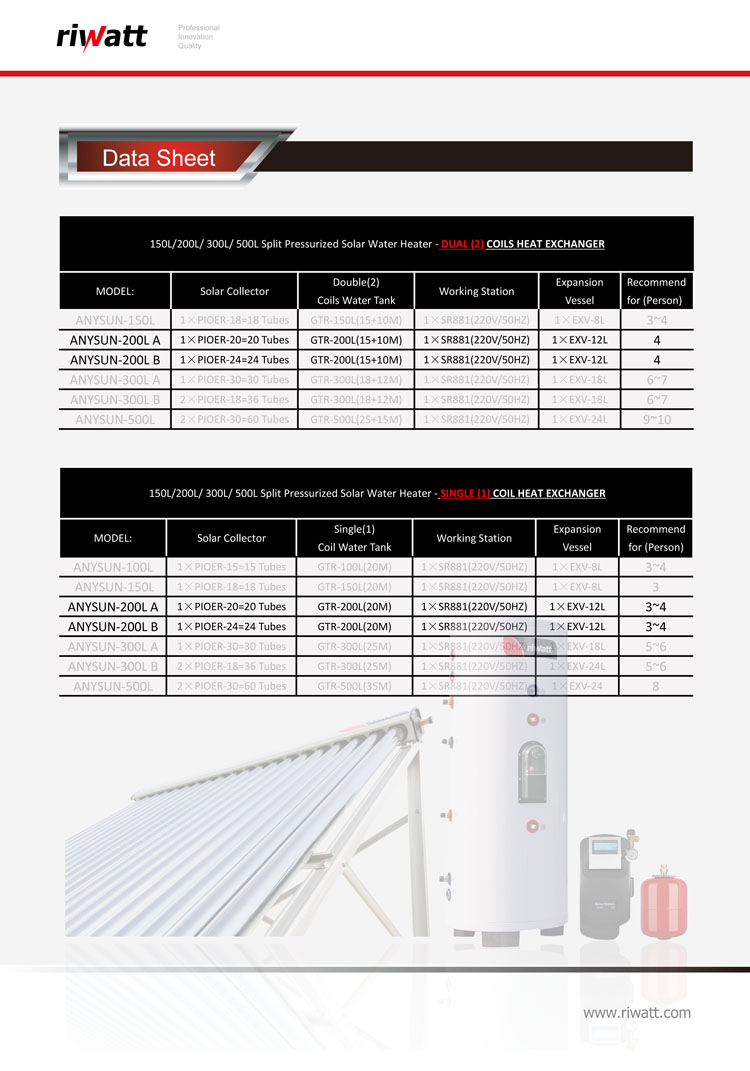

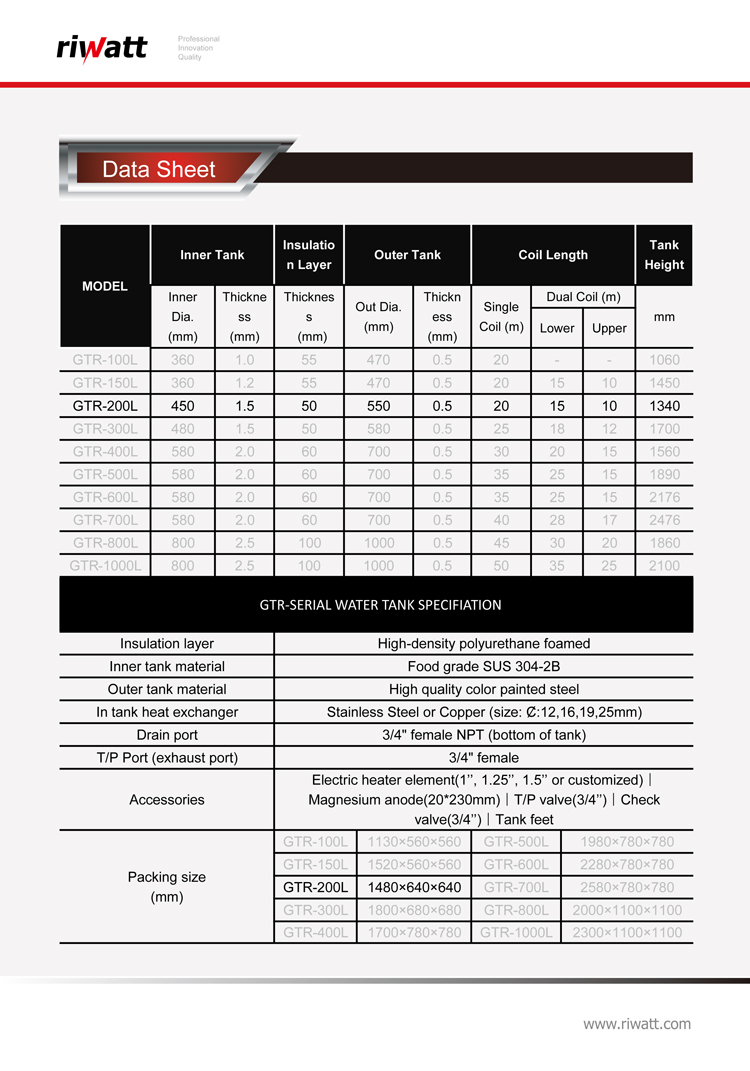

| Pressurized Water Storage Tank Data Sheet | |||||||||

| MODEL | Inner Dia. | Thickness | Thickness | Out Dia. | Thickness | Single Coil (m) | Dual Coil (m) | ||

| GTR-100L | 360 mm | 1.0 mm | 55 mm | 470 mm | 0.5 mm | 20 | – | – | |

| GTR-150L | 360 mm | 1.2 mm | 55 mm | 470 mm | 0.5 mm | 20 | 12 | 10 | |

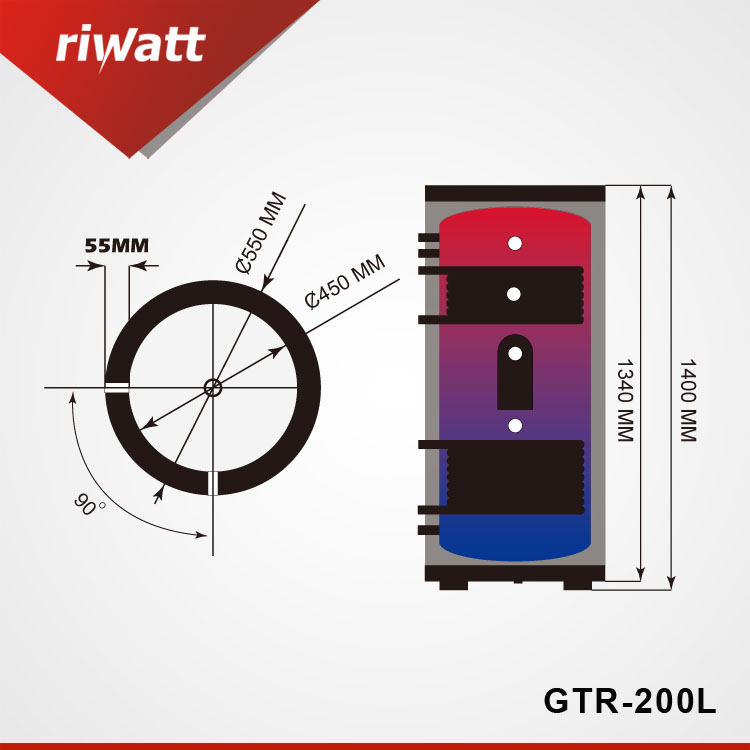

| GTR-200L | 450 mm | 1.5 mm | 50 mm | 550 mm | 0.5 mm | 20 | 15 | 10 | |

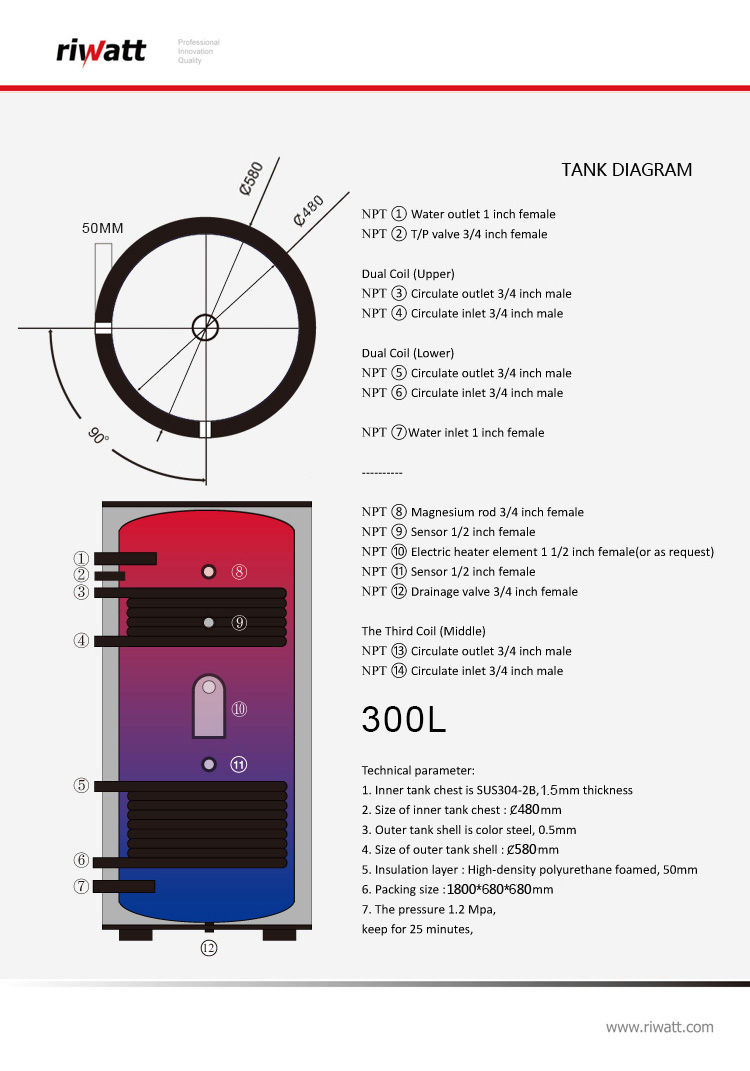

| GTR-300L | 480 mm | 1.5 mm | 50 mm | 580 mm | 0.5 mm | 25 | 18 | 12 | |

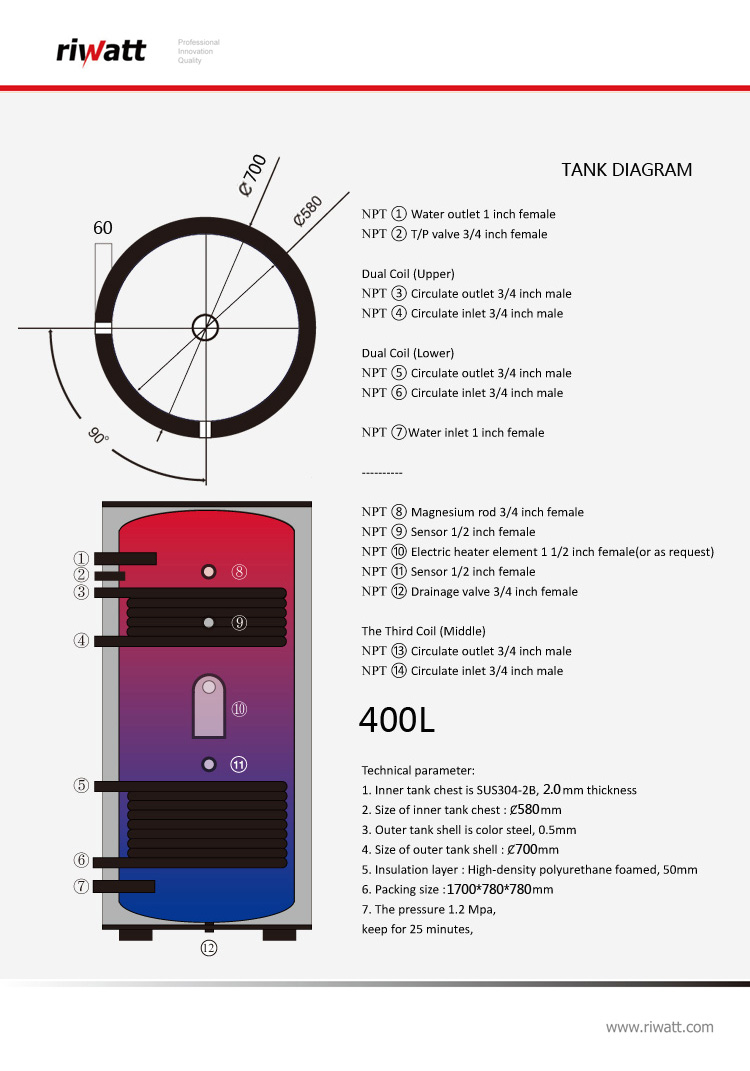

| GTR-400L | 580 mm | 2.0 mm | 60 mm | 700 mm | 0.5 mm | 30 | 20 | 15 | |

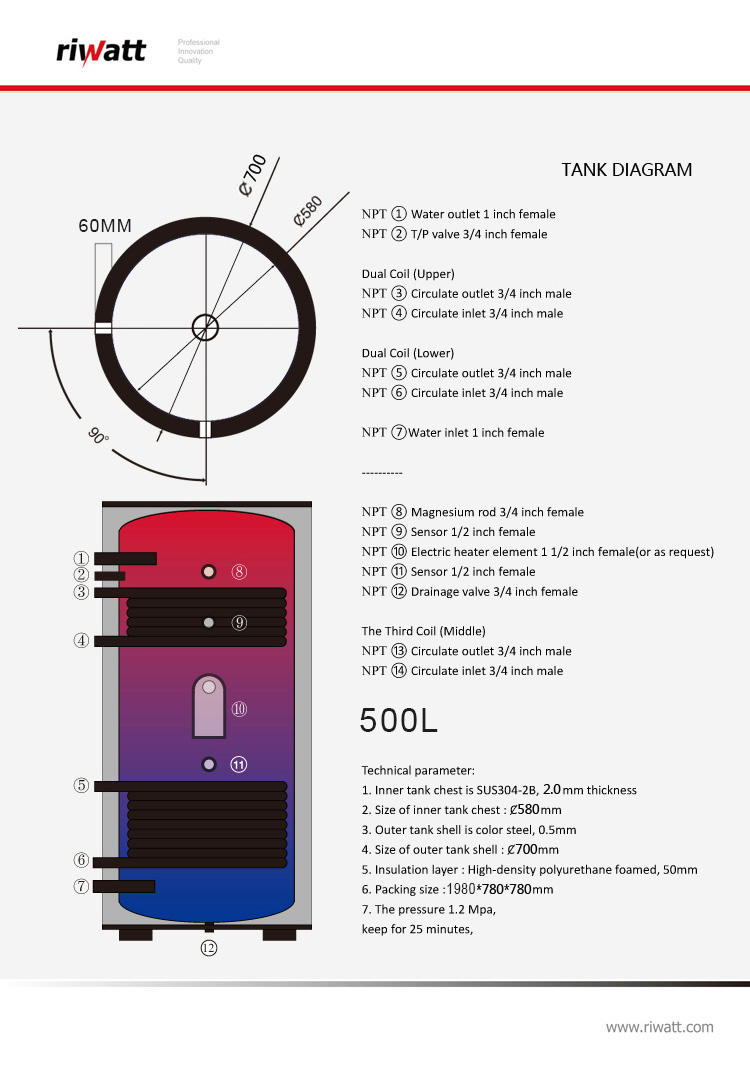

| GTR-500L | 580 mm | 2.0 mm | 60 mm | 700 mm | 0.5 mm | 35 | 25 | 15 | |

| GTR-600L | 580 mm | 2.0 mm | 60 mm | 700 mm | 0.5 mm | 35 | 25 | 15 | |

| GTR-700L | 580 mm | 2.0 mm | 60 mm | 700 mm | 0.5 mm | 40 | 28 | 17 | |

| GTR-800L | 800 mm | 2.5 mm | 100 mm | 1000 mm | 0.5 mm | 45 | 30 | 20 | |

| GTR-1000L | 800 mm | 2.5 mm | 100 mm | 1000 mm | 0.5 mm | 50 | 35 | 25 | |

| Pressurized Water Storage Tank Specification | |||||||||

| Insulation layer: | High-density polyurethane foamed | ||||||||

| Inner tank material | Food grade SUS 304-2B/316L | ||||||||

| Outer tank cover material | Painted steel | ||||||||

| Heat preservation layer | High pressure automatic polyurethane foaming layer | ||||||||

| Heat exchanger specs | TU1 copper (red copper) or stainless steel | ||||||||

| Drain port | 3/4″ female NPT (bottom of tank) | ||||||||

| T/P Port (exhaust port) | 3/4″ female NPT (for T/P Valve) | ||||||||

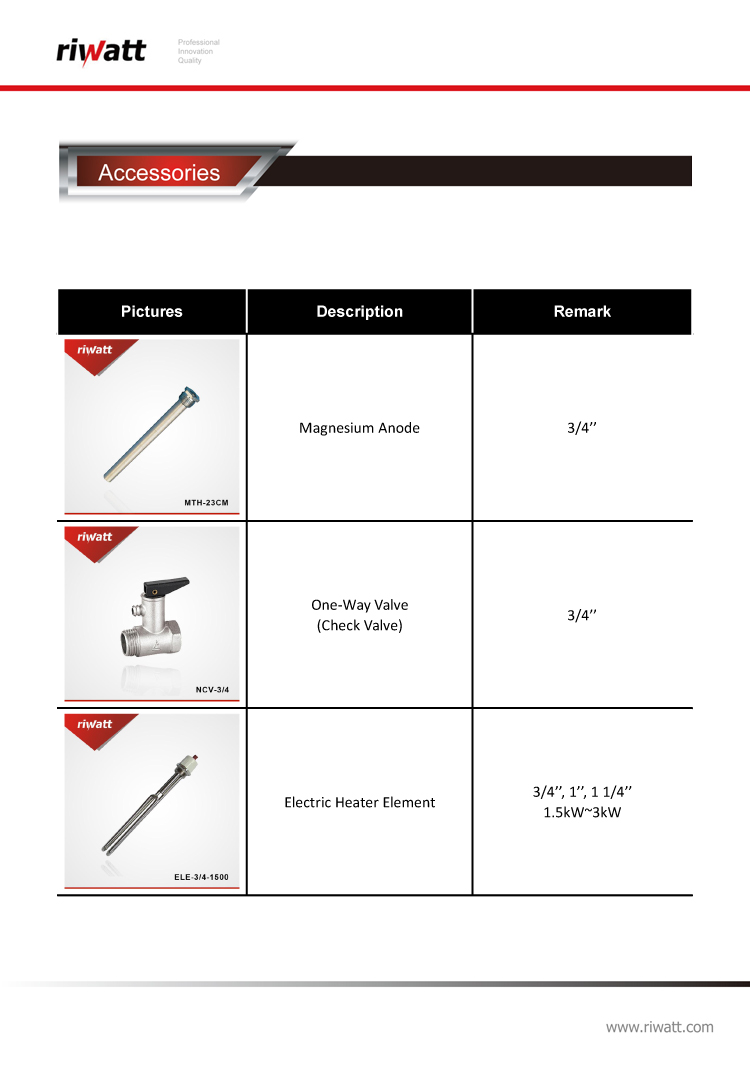

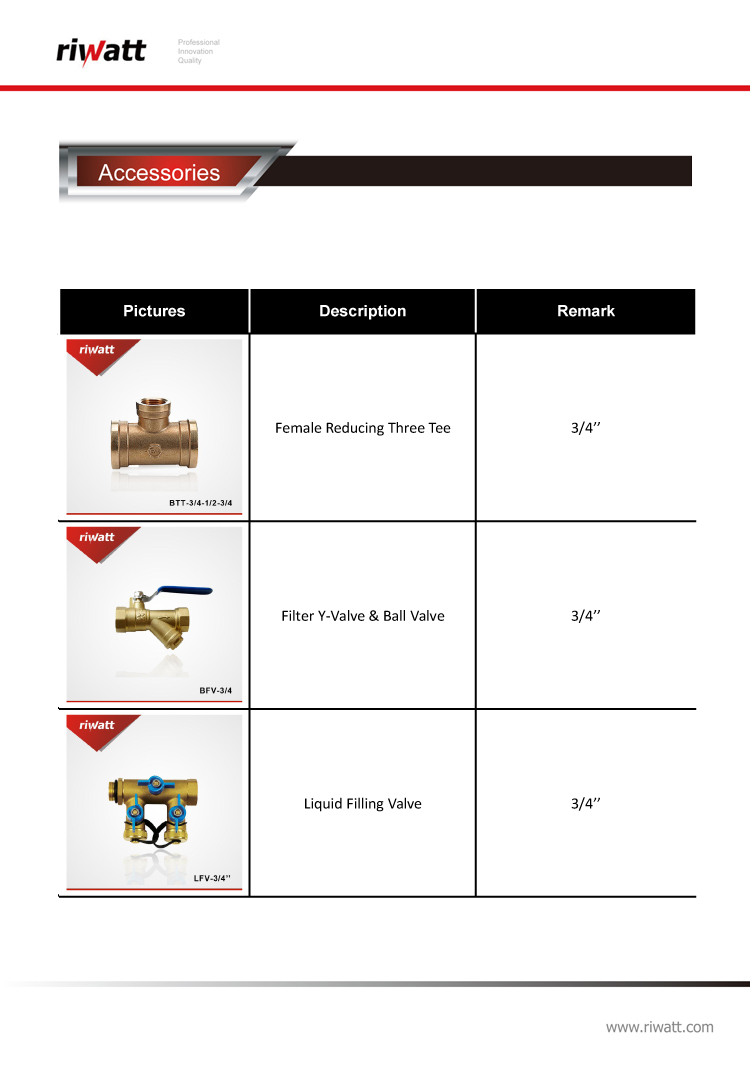

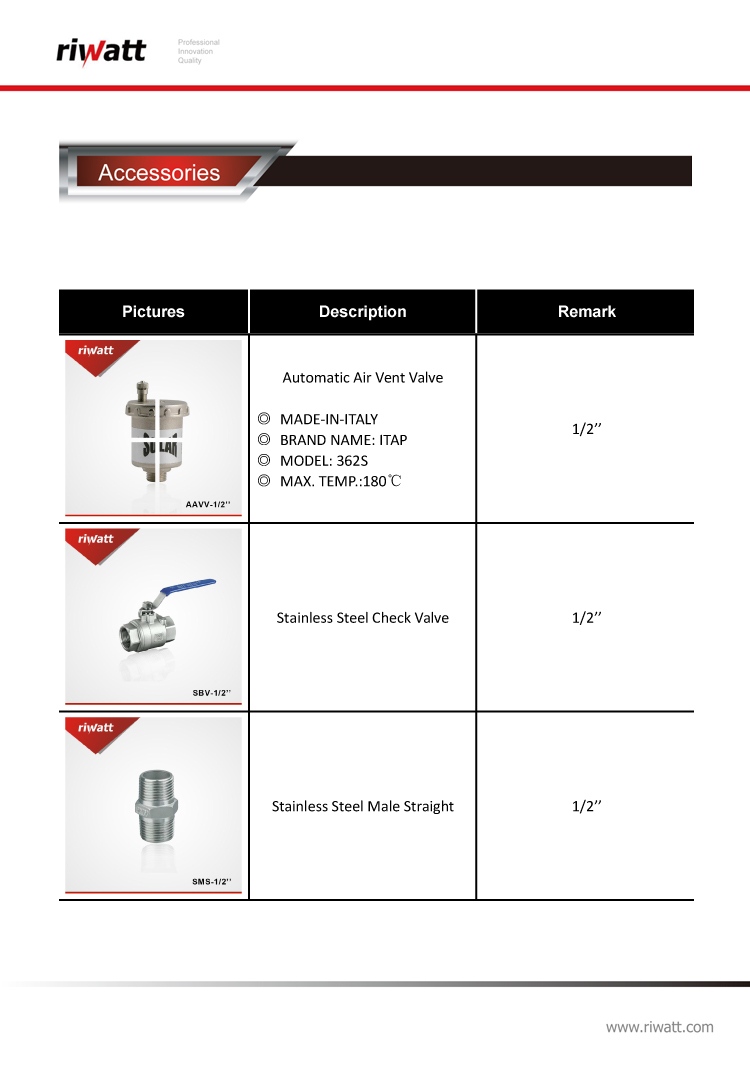

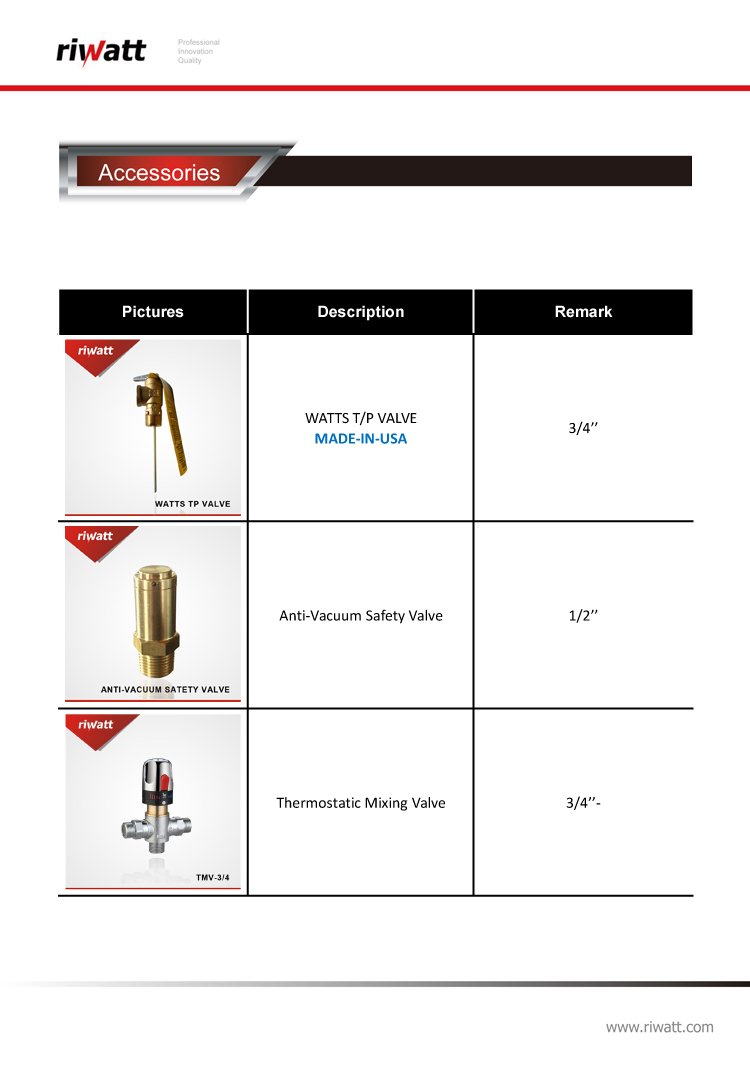

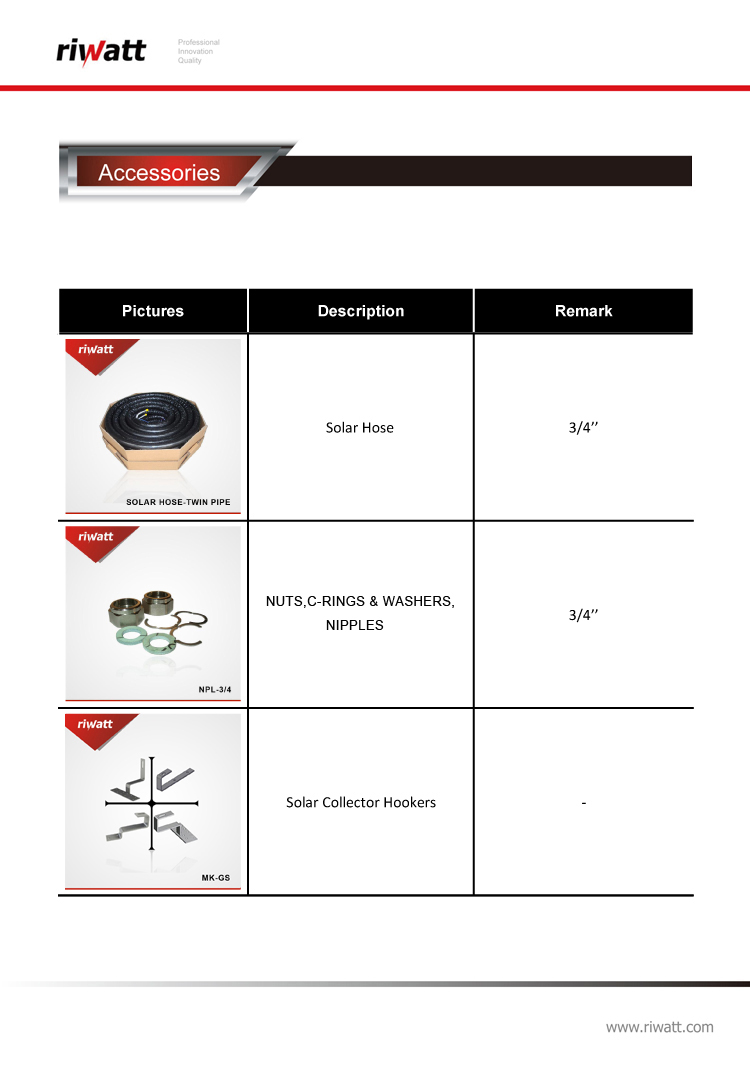

| Accessories | In-built electric heater element︱Magnesium anode︱T/P valve︱Check valve︱Tank feet︱Screws | ||||||||

| Packing Dimension(mm) | |||||||||

| GTR-100L | 1130×560×560 | GTR-500L | 1980×780×780 | ||||||

| GTR-150L | 1520×560×560 | GTR-600L | 2280×780×780 | ||||||

| GTR-200L | 1480×640×640 | GTR-700L | 2580×780×780 | ||||||

| GTR-300L | 1800×680×680 | GTR-800L | 2000×1100×1100 | ||||||

| GTR-400L | 1700×780×780 | GTR-1000L | 2300×1100×1100 | ||||||

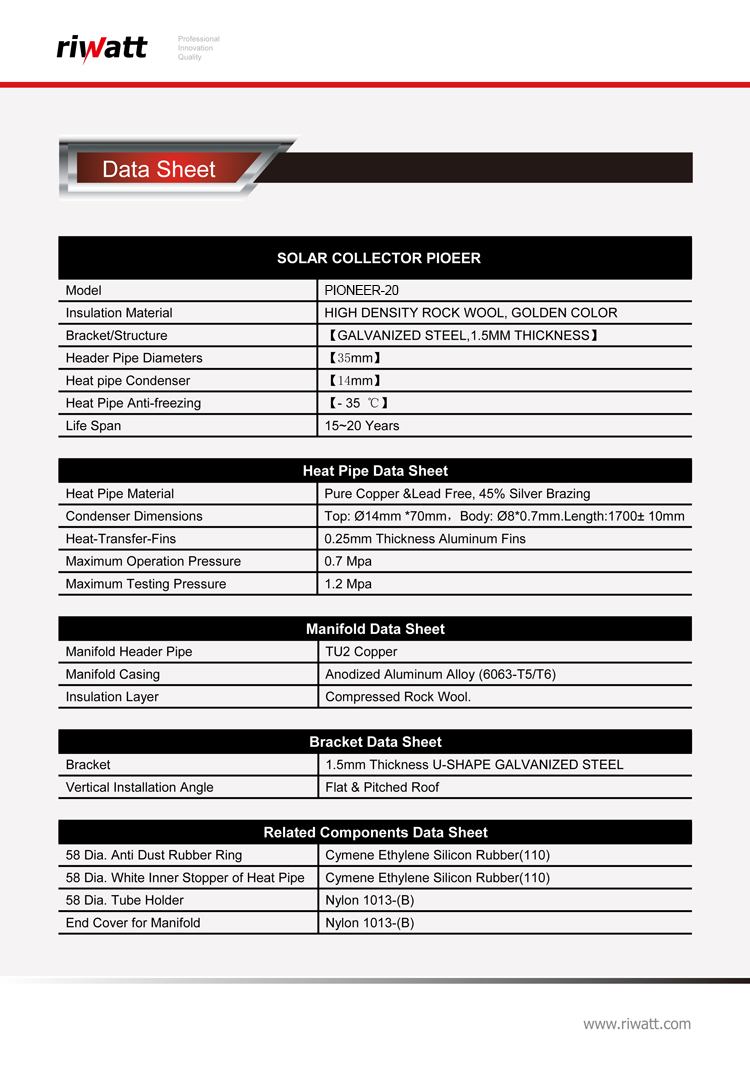

ANYSUN Serial High Pressure Solar Water Heater Specification:

1. Inner tank material:SUS304-2B stainless steel

2. Inner tank thickness:1.0/1.2/1.5/2.0/2.5mm

3. Outer tank material: ceramic white steel plate

4. Insulation layer:35/38/45mm high density polyurethane foam and 25mm aluminum silicate

5. Support material:2.mm import heat zinc steel plate or riwatt solar never rust al.alloy stand frame

6. Heater collector:new three target tube

7. Super Conducting riwatt BRAND heat pipe:High-purity copper system

8. Heater collectorsize: 10/12/15/20/24/30 tubes

9. Work station:instrument,expansion vessel,circulating pump,relife valve

10.Cubage: 100L,150L,200L,250L,300L,400L,500L

11. Heat collector working temperture: -37 to + 200 degree.

12. Electrical heater: 1.5 to 3KW.

13. Hot water temperature: 50-75

14. Pressure-endure ability:0.6~1.2Mpa

ANYSUN Serial High Pressure Solar Water Heater Trading Terms:

1. Payment terms: 30% in advance and 70% against B/L copy or 70% by L/C,

For sample T/T 100% in advance

2. Delivery terms: 15 working days after receiving deposit or original L/C.

3. Warranty: 7 years

4. Minimum quantity: 5 sets

Solar water heating systems use solar panels called ‘collectors’. They are normally fitted to your roof but can be ground or wall-mounted. These convert infrared light from the sun to heat water which is stored in a hot water cylinder. A boiler or immersion heater, or both, can be used as back up to heat the water further to reach the temperature you want when there is not enough sun to heat it fully. (This is also important to kill bacteria that can thrive in luke warm water.)

flat plate collectors, which can be fixed on top of roof tiles or integrated into the roof

evacuated tubes set in frames normally mounted on the roof

Solar thermal systems are generally sized on the basis of the number of bedrooms in the house and therefore the possible demand for hot water. If, however, you know that during the 20 year life of the system there will mostly only be, say, a couple in the house, then it will be more cost-effective to apply the rule of 1m2 of panel per person and ‘one for the house’ and try to source a competitively-priced system of this size. Collectors that are too large will spend much of the summer doing nothing but ‘cooking’ on the roof as the heated water is not used up so stays hot and does not circulate.

Sorry, no posts matched your criteria.

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.

WhatsApp us